Emerging Technologies: 3D Printing

3D printing is just what the name suggests. Usual 2D printers can print words to a page, but with 3D printers, one can do so much more. They allow us to create complex computerized designs and customize shapes using CAD—Computer-Aided Design. Once we’ve finished designing what we want, we can simply print it out. No need to mould or forge like in the old days. 3D printing is comparatively far faster and more efficient, with the ability to create very detailed designs.

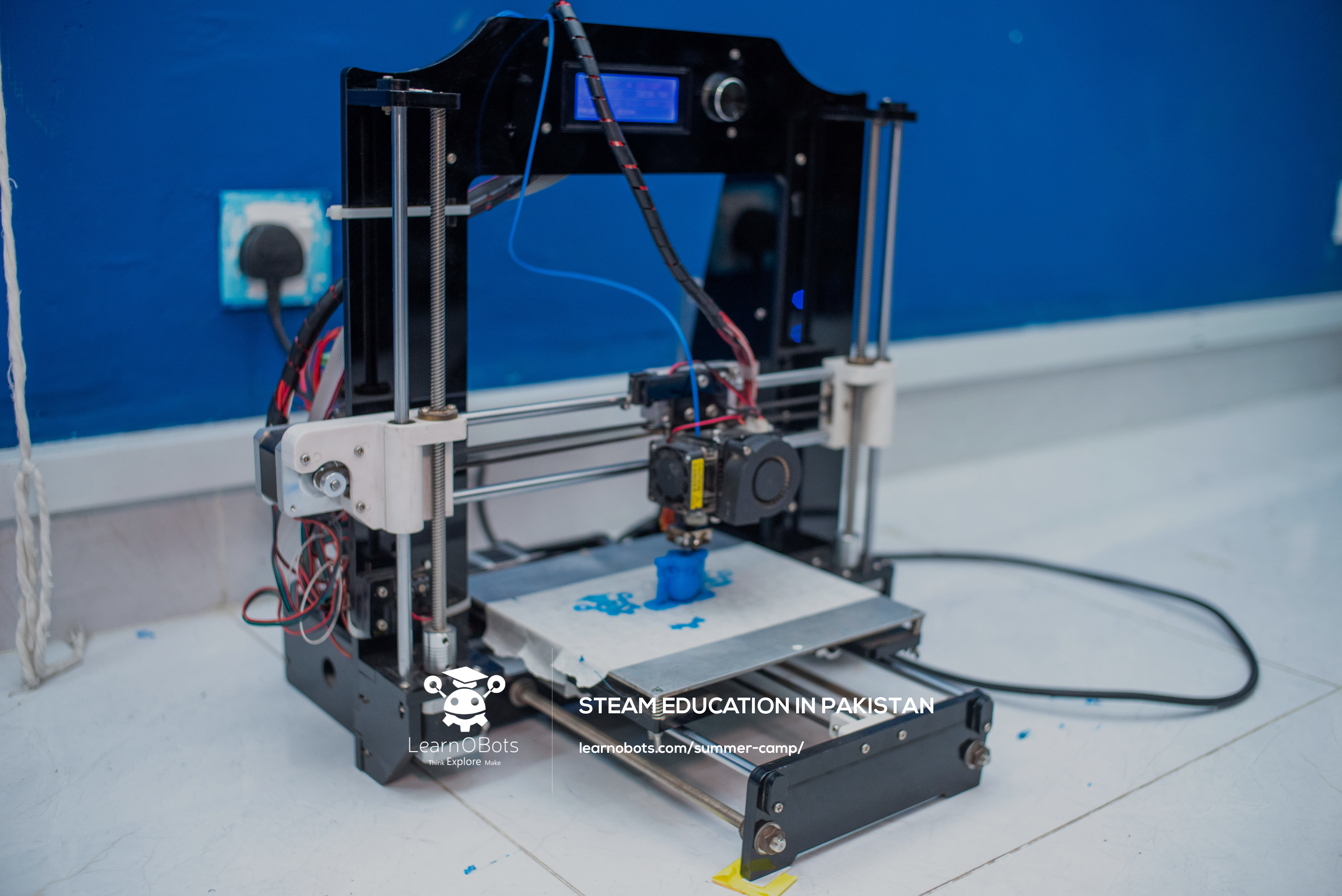

There are two major types of 3D printers, FDM and SLA. FDM, or Fused Deposition Modeling, also sometimes called Fused Filament Fabrication is the most popular type of 3D printing today. These printers push out filament through a heated nozzle which melts it and uses said filament to create designs layer by layer. FDM printed models have a characteristic layered texture due to how the printers form them. The procedure and the size of the nozzle also dictate the accuracy and precision of the printed model. Stereolithography or SLA, may not be the most popular form of 3D printing but it is the oldest, as Chuck Hull invented it in 1986. SLA uses a vat of gel which is solidified using lasers, and as such, it rests in more precise printing compared to FDM. SLA also gives the option to create transparent parts, which FDM doesn’t.

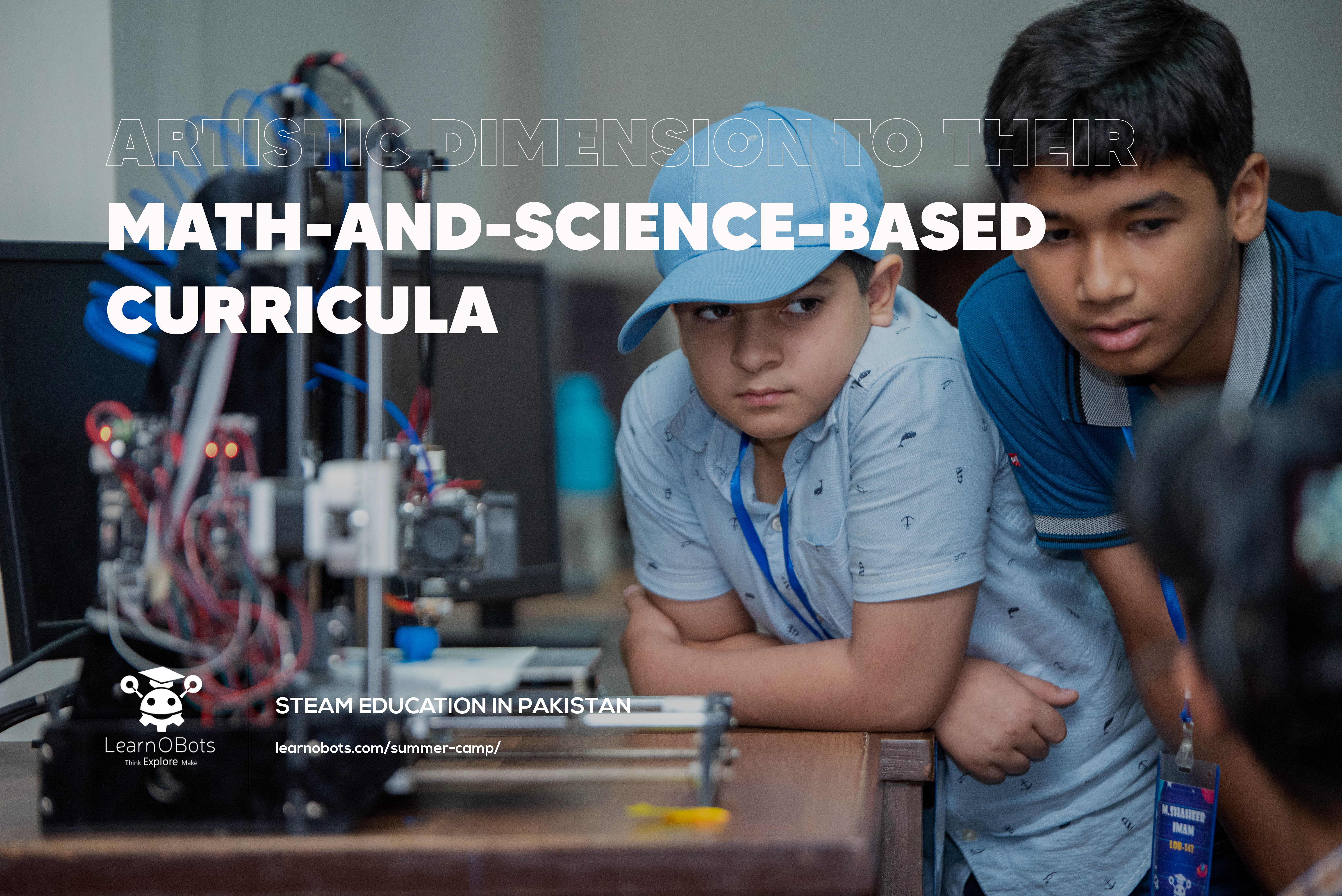

If you want to see an FDM 3D printer in person, come to LearnOBots’ STEAM Summer Camp! LearnOBots is a startup based in the National Science and Technology Park in Islamabad, and its goal is to bring state-of-the-art STEAM education to all Pakistani children. We offer classes on coding, DIY Kits and stay-at-home learning plans. At our Camps, children can learn new skills, make friends, and interact with robotics and 3D printing.

Uses of 3D Printers

Due to their versatility, we use 3D printers in several fields. The aerospace industry uses 3D printers to make new or customized parts. It offers great advantages as the parts are lightweight and material efficient. Moreover, instead of mass-producing parts, airlines and aeroplane manufacturers can create specific parts as needed. This also helps in repairing broken or damaged segments. 3D printing offers similar advantages to the automobile and vehicle manufacturing industry. Engineers can use computer simulations to identify the most aerodynamic shapes, and then make them through FDM or SLA.

Amputees can get customized prosthetic limbs made using 3D printers, which is especially useful for children who are still growing, as they need to switch prosthetics quite often. Doctors can also create implants or surgical instruments, and dentists can scan teeth and make dentures, crowns or bridges. Science has even opened the door to printing organs using organic tissue. This could help end the shortage of organ donors worldwide!

We can use 3D printing to create unique and high-performance small parts for both consumer and industrial purposes. But we can also use them to print on a much larger scale. Thinking Huts, a Madagascar-based NGO, started 3D printing entire schools in 2021! Using cement and a large-scale FDM set-up, they constructed entire buildings in a matter of days, significantly cutting down on costs as well. This could be game-changing for Pakistan, where almost half of the school-age children are not in school, and the brick-making industry employs gross amounts of bonded and child labour. It would be akin to killing two birds with one stone.

Advantages and Disadvantages

As already discussed, 3D printing allows for quick and easy prototyping using computer software. We can custom print complex designs which would be difficult to build by hand. 3D designs can be saved as files and shared around the world, and because of this, they can be made on-demand. This also solves many inventory issues, as there is no need to order them in or stock up on them. 3D printed parts are lightweight, strong, cost-effective and use little material. They are environmentally friendly and sustainable as they reduce and minimise waste involved in production. Moreover, aeroplanes with 3D printed parts weigh less and thus use less fuel. 3D printing can be used to save lives with its medical applications, and it has impacts on almost all industries.

3D printing, like all technologies, has its downsides as well. In Pakistan, to own a 3D printer, one must pass several qualifications and it is otherwise illegal to own them. This is because of the threat of people using them to print out guns or other weapons. Because CAD designs can be shared online, anyone could download blueprints for a gun without proper authorization from the Government and use them to commit violence.

3D printing also has some other disadvantages. Though it is relatively quick, the process is still too slow for mass production. There are also limitations on the size of things that can be printed, and printouts from FDM have a limit to their precision. Nonetheless, 3D printing offers a plethora of solutions to our problems. We can deal with the disadvantages as we further develop the technology. Lawmakers can pass legislation to make sure that extremists don’t use it to create weapons. Overall, it is one of the top technologies changing the world for the better.